Pile head breaker, also known as a pile breaker or hydraulic pile breaker, is a specialized hydraulic tool used for removing excess concrete from the tops of foundation piles. It is typically attached to an excavator, crane, or other carrier and is designed to break the concrete pile head accurately at a predetermined height. Pile head breaking machine can handle various pile diameters and shapes—circular, square, or rectangular—making them suitable for different construction needs. They are widely used in bridge construction, high-rise buildings, power plants, and civil engineering projects.

Technical Data of Pile Head Breaker

| Model | YG-800 | YG-980 | YG-1150 | YG-1300 | YG-1500 | YG-1650 | YG-1800 | YG-2000 | YG-2150 | YG-2300 | YG-2500 |

| Applicable pile diameter | 600-800mm | 800-900mm | 1100-1150mm | 1150-1300mm | 1300-1500mm | 1500-1650mm | 1650-1800mm | 1800-2000mm | 2000-2150mm | 2150-2300mm | 2300-2500mm |

| Number of modules | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Machine weight | 2400kg | 2700kg | 3000kg | 3300kg | 3600kg | 3900kg | 4200kg | 4500kg | 4800kg | 5100kg | 5400kg |

| Applicable excavator model | 20-30T | 20-30T | 20-30T | 30-40T | 30-40T | 30-40T | Hydraulic pump station | Hydraulic pump station | Hydraulic pump station | Hydraulic pump station | Hydraulic pump station |

| Cylinder stroke | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm |

| Working pressure | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa |

| Oil storage capacity of a single module | 5L | 5L | 5L | 5L | 5L | 5L | 5L | 5L | 5L | 5L | 5L |

| Breaking force | 70T | 70T | 70T | 70T | 70T | 70T | 70T | 70T | 70T | 70T | 70T |

Structure and Components of the Pile Head Breaker

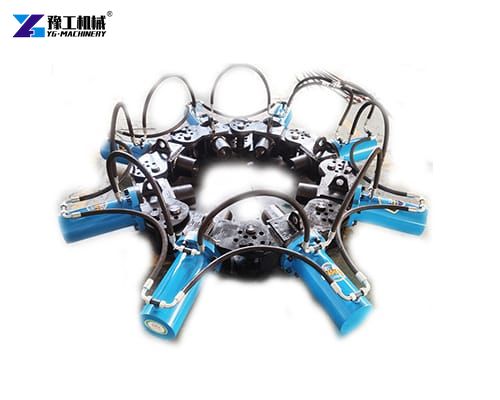

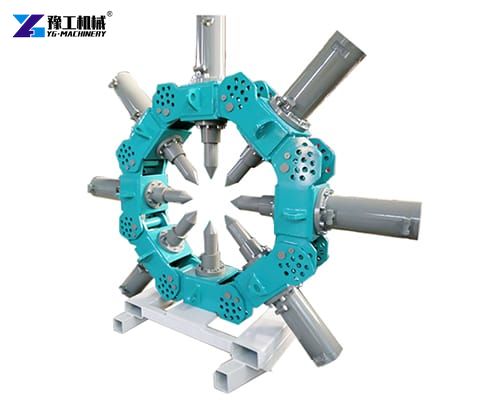

A standard pile breaker machine consists of several key components that work together to ensure safe and efficient pile removal:

- Modular Hydraulic Cylinders

The breaker is made up of multiple hydraulic cylinders arranged in a circular frame. Each cylinder can be individually controlled to apply even pressure around the pile. - Connecting Frame

The frame holds the hydraulic modules together and can be adjusted according to the pile diameter, making the system highly flexible for different project needs. - Quick Couplers and Hoses

High-pressure hydraulic hoses connect the breaker to an excavator or power pack. Quick couplers make assembly and disassembly simple and safe. - Control System

The operator can control the hydraulic pressure and working cycle through a centralized control system, ensuring precision during pile cutting. - Lifting Chains or Brackets

The pile head breaker is often suspended from an excavator or crane using lifting chains or steel brackets, allowing for easy positioning over the pile head.

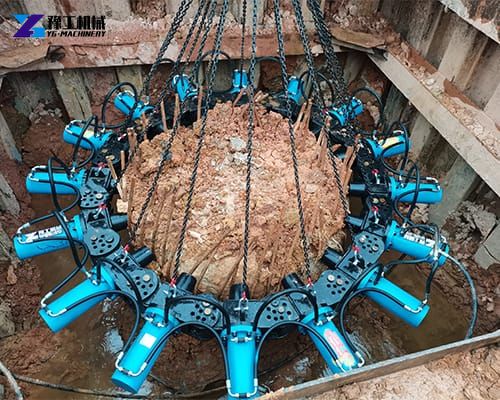

Working Principle of the Concrete Pile Breaker

- The breaker is positioned over the pile head using an excavator or crane.

- Hydraulic oil is supplied from the excavator’s power system to the breaker’s hydraulic cylinders.

- The cylinders apply uniform pressure around the pile head.

- As the pressure increases, the concrete breaks along the designed cutoff level.

Advantages of Using a Pile Head Breaker

- High Productivity: The machine drastically reduces the time needed to break piles compared to manual methods.

- Cost-Effectiveness: Lower labor costs and reduced project duration make it an economical choice.

- Structural Integrity: Controlled breaking prevents micro-cracks or damage to the remaining pile body.

- Environmental Benefits: The hydraulic operation produces little noise and no vibration, minimizing environmental disturbance on-site.

- Precision and Consistency: The adjustable hydraulic pressure ensures uniform cutting levels across multiple piles.

Applications of Concrete Pile Breaker

Pile head breakers are used in a wide range of construction and infrastructure projects, including:

- Building Foundations: For cutting reinforced concrete piles in residential and commercial projects.

- Bridge Construction: Ensures even pile tops for stable bridge piers.

- Port and Wharf Projects: Used in marine pile foundations where precision and safety are essential.

- Highway and Railway Foundations: For large-diameter pile breaking in transportation infrastructure.