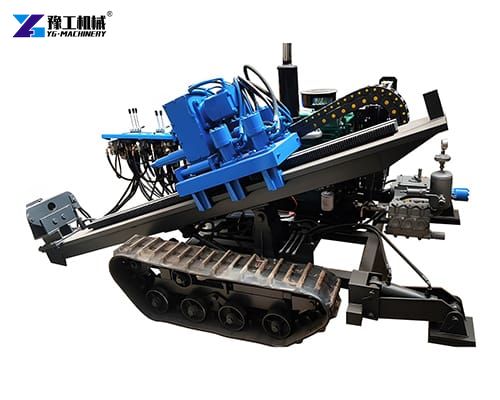

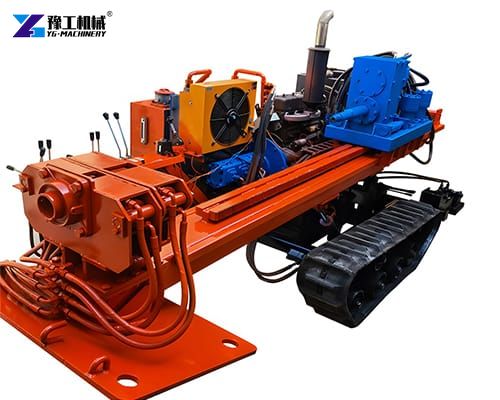

Horizontal drilling machine for sale, also known as a horizontal directional drilling (HDD) rig, is a specialized trenchless drilling rig used to install underground pipes, conduits, or cables horizontally beneath obstacles (roads, rivers, buildings) with minimal surface disruption. Different from vertical drills, HDD machines steer along a precise curved path using a guided pilot bore, which is later enlarged to pull back the utility line. If you are looking for this machine for construction, mining, or industrial manufacturing, our cutting-edge horizontal drilling equipment delivers unmatched precision, efficiency, and durability. Designed for heavy-duty applications, these machines are built to handle tough terrains and demanding projects.

Parameters of Horizontal Drilling Machine for Sale

| Model | YG-50LS | YG-130LS | YG-150LS | YG-200LS |

| Weight | 3650kg | 4750kg | 4700kg | 8800kg |

| Max. Thrust & Pullback Force | 51kN | 135kN | 150kN | 205kN |

| Max. Torque | 2235N·m | 4500N·m | 4500N·m | 6500N·m |

| Engine Power | 43kw | 93kw | 93kw | 113kw |

| Walking Speed | 2.5km/h | 2.5-4.5km/h | 2.5-4.5km/h | 2.5-4km/h |

| Entry Angle | 14°-17° | 12°-22° | 12°-22° | 12°-22° |

| Drill Rod Size | φ42*1800mm | φ50/φ60*3000mm | φ60*2000mm | φ60*3000mm |

| Suggest Reaming Diameter | ≤φ400mm | ≤φ700mm | ≤φ700mm | ≤φ800mm |

| Dimension(L*W*H) | 3870*1300*1470mm | 5470*1670*2040mm | 4200*1700*2140mm | 6750*2050*2400mm |

| Max. Thrust & Pullback Speed | 61m/min | 36m/min | 46m/min | 60m/min |

| Max. Rotation Speed | 215r/min | 193r/min | 193r/min | 230r/min |

| Max. Mud Flow | 75L/min | 200L/min | 180L/min | 250L/min |

| Max. Mud Pressure | 6Mpa | 8Mpa | 8Mpa | 8Mpa |

| Max. Climbing Gradient | 17° | 16° | 17° | 17° |

| Drill Rod Box Capacity | 44pcs(4*11) | 48pcs(4*12) | 56pcs(4*14) | 48pcs(4*12) |

| Suggest Crossing Length | ≤100m | ≤200m | ≤200m | ≤300m |

Features of Horizontal Drilling Machine for Sale

- Trenchless Technology:

Avoids excavation, reducing environmental impact, traffic disruption, and restoration costs. - Steering & Guidance:

Equipped with electronic tracking systems for real-time path accuracy. - Power & Capacity:

Ranges from compact rigs for urban fiber optics to massive units for cross-country pipelines.

Why Choose the HDD Rig Machine?

- Durability: Built to handle tough drilling conditions.

- Efficiency: Save time and labor with advanced controls.

- Safety: Designed with operator protection and job site safety in mind.

- Cost-Effective: Lower operational and maintenance costs.

- Support: Expert technical support and spare parts available anytime.

Benefits of Horizontal Directional Drilling Rigs

- Versatility: Horizontal drilling machine for sale is capable of drilling through various soil conditions, including clay, sand, gravel, and rock.

- Precision Control: Advanced guidance systems for accurate bore paths, minimizing environmental impact, and maximizing efficiency.

- Powerful Performance: High thrust and pullback capabilities to handle demanding pulls and large pipe diameters.

- Reliability: Built with robust components and engineered for long-term, heavy-duty use.

- Cost-Effectiveness: Optimize project timelines and reduce restoration costs compared to traditional trenching methods.