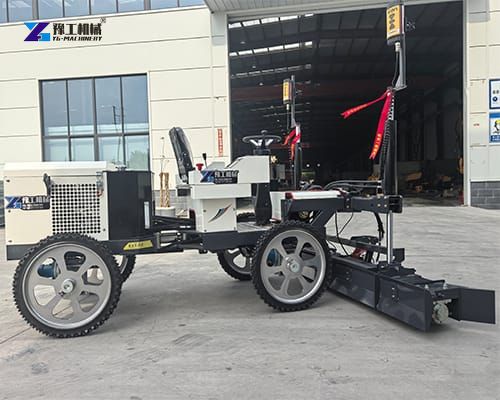

2.5m concrete laser leveling machine sold to Dubai. Our client works for a company that specializes in industrial floors for warehouses, logistics centers, and parking structures. They faced a familiar problem. Labor costs were rising, project timelines were tightening, and clients were demanding higher flatness standards for large concrete slabs. Traditional screeding methods were no longer enough. So they knew it was time to upgrade. He came across our website while searching for this machine. He reached out through our inquiry form, requesting specifications, pricing, and delivery time. Our sales manager provided several solutions for choosing based on their requirements. They finally chose the 2.5m type.

Parameters of the 2.5m Concrete Laser Leveling Machine Sold to Dubai

| Model | YG-CL300 |

| Engine model | Briggs & Stratton 38E3/LONCIN/Honda 690 (optional) |

| Engine type | Gasoline, air-cooled 4-stroke, twin-cylinder engine |

| Engine power | 22KW/30ps |

| Fuel capacity | 20L (operation time is about 8 hours |

| Hydraulic oil capacity | 37L |

| Laser transmitter | Swiss Leica/Tower transmitter (optional) |

| Laser receiver | Swiss Leica/Tower receiver (optional) |

| Laser system control effect | Plane, slope, double slope (three-dimensional) |

| Laser system control method | Microcomputer laser scanning |

| Paving method | Hydraulic stirring cage paving |

| Vibration method/excitation force | Hydraulic vibration/2000N |

| Vibration plate width | 2500mm |

| Leveling thickness | 50-300mm |

| Travel drive | Reducer motor integrated |

| Travel speed | 0-4Km/h (speed adjustable) |

| Travel tire | Solid anti-skid and anti-puncture tires (optional wide tires) |

| Body size | 3250x2850x1320mm |

Why Is the Concrete Laser Levelling Machine Important?

- Scale meets precision: With a 2.5-meter effective levelling span, this laser levelling machine is designed for large slabs, runways, and expansive concrete pours where conventional tools slow you down.

- Laser accuracy, real-world impact: High-precision laser guidance ensures consistent elevation and slope across long distances, reducing rework and material waste.

- User-friendly workflow: Intuitive controls, automated calibration, and fast setup mean crews spend less time aligning equipment and more time building.

- Consistency across big slabs: In high-rise basements, parking structures, and commercial slabs, maintaining uniform grade over wide areas is critical. This tool delivers that consistency with each pass.

- Harsh conditions, dependable results: The concrete laser leveling machine is built to handle dusty sites, high temperatures, and long shifts, delivering stable readings even in tough environments.

Wide Applications for Different Projects

- Commercial and residential slabs: Whole-floor pours require evenness across wide areas; this tool helps ensure a level base for finishes, tiling, and equipment placement.

- Parking structures and basements: Large, flat surfaces demand precise levelling to avoid costly corrections later.

- Runways and airside areas: Precision in elevation and cross-slope control is essential for safe, long-term performance.

- Industrial facilities: Large factory floors benefit from uniform grade for equipment alignment and forklift operations.