Paper slitting and rewinding machine is an advanced industrial equipment designed to cut large rolls of paper, film, or other flexible materials into smaller, precise widths while simultaneously rewinding them onto new cores. These machines play a crucial role in industries such as printing, packaging, paper manufacturing, and the processing of convertible materials. By automating the slitting and rewinding process, they enhance productivity, reduce labor costs, and ensure consistent product quality.

Parameters of the Paper Slitting Rewinding Machine

| Model | YG-1100A | YG-1300A | YG-1600A | YG-1800A |

| Max. Unwinding width | 1100mm | 1300mm | 1600mm | 1800mm |

| Max. Unwinding diameter | 1400mm | 1400mm | 1400mm | 1400mm |

| Max. Rewinder diameter | 1000mm | 1000mm | 1000mm | 1000mm |

| Min. Rewinder web width | 50mm | 30mm | 30mm | 30mm |

| Slitting speed | 10-350 m/min | 30-500m/min | 30-500m/min | 30-500m/min |

| Precision of slitting | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

| Slitting thickness | 20-200g (paper) | 15-500g/m² | 15-500g/m² | 15-500g/m² |

| Total power | 25kw | 26kw | 26kw | 38kw |

| Machine weight | 5600kg | 4500kg | 5200kg | 6000kg |

| Overall dimension | 4200*3200*1950mm | 4500*2800*1950mm | 4500*3200*1950mm | 4500*3800*1950mm |

Features of Paper Roll Slitting Machine

- High precision slitting system

The accuracy of the slitting mechanism directly affects product quality and reduces waste. - Advanced tension control

Good tension control ensures the web does not wrinkle, tear, or drift. - Durable unwinding and rewinding units

Unwind stands are designed to hold large-diameter parent rolls. Rewinders ensure each final roll is wound evenly, with consistent density and perfect roll formation. - Automatic controls

Many high-end models feature touchscreens, PLC systems, automatic blade positioning, fault detection, and programmable settings for different materials.

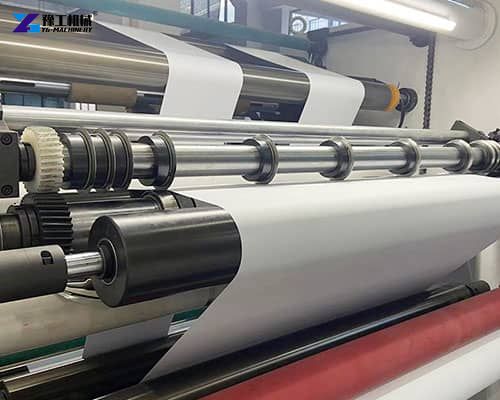

Components of the Slitting and Rewinding Machine

- Unwind stand

This holds the parent roll and typically features a pneumatic shaft, hydraulic lifting system, and braking unit to maintain tension. - Tension control units

Located at the unwind, midsection, and rewinder, these units manage web force and ensure consistent handling. - Slitting section

This is where the cutting happens. Depending on the paper slitting and rewinding machine, it may use razor blades, shear knives, or crush cutting technology. - Rewinding section

The slit strips of paper are rewound onto new cores. Rewind systems can be center-driven, surface-driven, or combination styles. - Control panel

Operators control speed, tension, blade setup, alignment, and monitoring through a user-friendly interface.

Advantages of Using A Paper Slitting Machine

- Enhanced productivity

The paper slitting and rewinding machine can convert large parent rolls into multiple finished rolls in a single cycle, significantly increasing output. - Improved quality control

Consistent slitting accuracy results in smooth edges, uniform roll density, and stable material behavior during downstream processes. - Reduced waste

Advanced slitting blades and tension systems minimize edge damage, wrinkles, cuts, and other defects that lead to scrap. - Cost efficiency

Better yield, reduced labor, automation options, and fewer defective rolls lower overall production costs.

Working Principle of Roll to Roll Slitting Machine

- A parent roll is loaded onto the unwind stand of the paper slitting and rewinding machine.

- The paper web unrolls and passes through guiding rollers and tension control units.

- The web enters the slitting section, where evenly positioned knives cut the paper into narrower strips.

- Each strip is rewound onto its own core with controlled torque and speed to create tightly wound individual rolls.

- Finished rolls are removed and prepared for packaging or further processing.

Throughout the system, tension, blade sharpness, alignment, and roller synchronization determine the final quality.

Main Applications in Different Industries

- Printing and publishing

Paper rolls used for newspapers, magazines, books, and digital printing all require precise slitting. - Packaging and labeling

Carton manufacturers, adhesive label producers, and flexible packaging converters depend on accurate roll widths. - Industrial paper production

Kraft paper, corrugated liners, and specialty technical papers need exact specifications. - Food service and hospitality

Baking paper, food wrapping paper, and aluminum foil manufacturers rely on these machines.