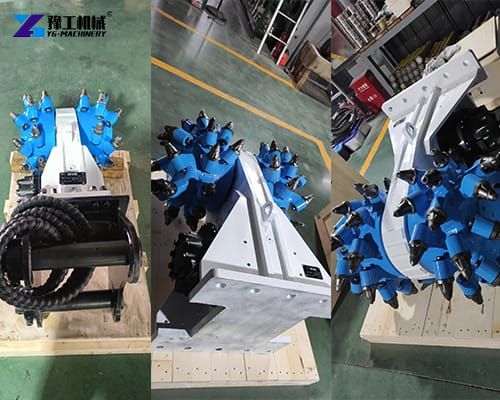

Drum cutter machine, also known as a rotary drum cutter or milling head, is a powerful hydraulic attachment designed for cutting, milling, and trenching through exceptionally hard and abrasive materials. Imagine a massive, robust cylinder, or drum, rotating on its axis, its surface studded with an array of tough, strategically placed cutting tools. This is the essence of a drum cutter. The drum cutter operates on a milling principle. It mechanically chips away material in a controlled, continuous process, resulting in a cleaner cut, less vibration, and significantly reduced noise. They are typically mounted on carriers such as excavators, skid-steer loaders, or specialized mining equipment. The hydraulic system of the host machine provides the necessary power to rotate the drum at high torque and to press it against the working face with immense force. This synergy between the carrier and the drum cutter attachment creates a versatile and highly effective cutting solution for a multitude of challenging applications.

Drum Cutter Machine Specifications

| Product Model | ZX-1 | ZX-2 | ZX-3 | ZX-4 |

| Applicable Models | 6-9T | 10-18T | 20-27T | 30-40T |

| Machine Weight | 340kg | 480kg | 900kg | 1100kg |

| Milling Head Diameter | 400mm | 450mm | 550mm | 580mm |

| Number of Blade Heads | 28 | 32 | 44 | 48 |

| Recommended Speed | 80r/min | 80r/min | 75r/min | 65r/min |

| Recommended Flow Rate | 75L/min | 120L/min | 200L/min | 260L/min |

| Maximum Pressure | 35Mpa | 35Mpa | 35Mpa | 35Mpa |

| Maximum Torque | 3780NM | 7900NM | 12700NM | 19600NM |

Features of Drum Cutter Machine

- Hydraulic Power Integration

The drum cutter is powered by the excavator’s hydraulic system, ensuring strong torque and continuous performance even under heavy load conditions. - High Precision Cutting

Its design allows for exact profiling and shaping of surfaces, making it ideal for excavation tasks that require precision, such as trenching for pipelines or cable laying. - Low Noise and Vibration

The cutting process is smooth and continuous, reducing environmental impact and ensuring safer operation in urban areas or near sensitive structures. - Interchangeable Drums And Teeth

Users can easily replace the cutting drums or teeth depending on the hardness of the material, increasing flexibility and minimizing downtime. - Durable Construction

Made from wear-resistant steel and equipped with high-strength bearings, the machine offers exceptional longevity even in abrasive environments.

Versatile Applications Across Industries

- Trenching and Utility Installation: Precise cutting for pipelines, cables, and infrastructure with minimal over-excavation.

- Tunneling and Underground Mining: Shaping and profiling tunnel faces, creating stable surfaces, and working in confined spaces.

- Concrete and Asphalt Milling: Drum cutter machine removes layers of road surface, bridge decks, and concrete structures.

- Demolition and Surface Preparation: Controlled dismantling of walls, foundations, and preparation of rock faces for stabilization.

- Frozen Ground and Earthworks: Cutting through permafrost or highly compacted ground where other methods fail.

Unmatched Operational Advantages

- Precision and Selectivity: Ability to cut precise shapes and depths, minimizing damage to surrounding structures.

- Cost-Effectiveness: Reduced need for secondary crushing or disposal due to smaller aggregate size; lower wear and tear on the carrier compared to a hammer.

- Environmental Benefits: Minimal dust generation (especially with water injection), low noise pollution, and often eliminates the need for blasting (a major safety and environmental advantage).

- Safety Improvement: Controlled material removal reduces the risk of fly rock and uncontrolled demolition.

How to Choose the Right Drum Cutter Machine

Selecting the right drum cutter depends on several factors, including your project requirements, excavator size, and material type. Here are key points to consider:

- Excavator Compatibility

Always match the cutter’s hydraulic flow and pressure requirements with the excavator’s capacity. - Material Hardness

Choose the cutter model and teeth type according to the hardness of the material to ensure efficient cutting and minimal wear. - Cutting Width And Depth

Different drum sizes allow for varying cutting depths. Select a cutter that suits your trench or excavation dimensions. - Weight And Balance

The drum cutter attachment should not exceed the excavator’s lifting and balance capacity to maintain stability and performance.