Concrete floor leveling machine is specialized equipment used to level and smooth freshly poured concrete surfaces. These machines utilize advanced laser technology or mechanical leveling systems to ensure a flat, uniform, and perfectly aligned surface. The main objective is to eliminate manual errors, reduce labor intensity, and increase the speed and accuracy of concrete finishing.

Features of a Concrete Laser Leveling Machine

- Laser Control System: Ensures high precision and automatic elevation control.

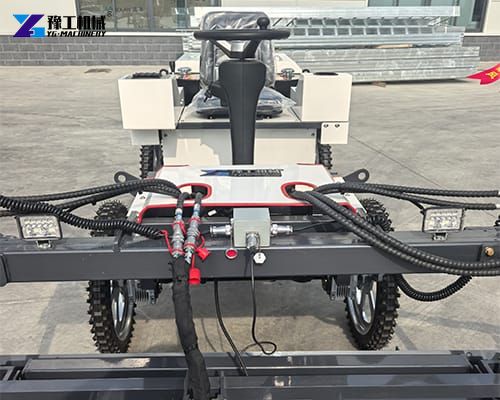

- Hydraulic or Electric Drive System: Provides power and control for smooth operation.

- Adjustable Screed Head: Allows customization for different floor sizes and project requirements.

- Integrated Vibration System: Improves concrete density and finish quality.

- User-Friendly Controls: Simplifies operation and reduces the need for specialized training.

- Robust Frame and Chassis: Ensures durability and long-term reliability, even under tough conditions.

How Does A Concrete Floor Leveling Machine Work?

Concrete laser leveling machines use laser-guided systems to ensure unparalleled accuracy during the leveling process. The machine’s laser receiver detects a reference beam emitted by a transmitter, automatically adjusting the screed head to maintain the exact elevation and slope required. This eliminates human error and guarantees a perfectly level finish, even across vast areas. The process begins by setting up laser transmitters around the construction site to establish a reference plane. The machine’s operator then guides the equipment across the freshly poured concrete. As the machine moves, its screed head vibrates to compact the concrete while smoothing it to the desired thickness. Simultaneously, the laser system continuously adjusts the height, compensating for any irregularities in the subgrade or concrete consistency.

Benefits of Using Laser Concrete Leveling Machine

The adoption of concrete floor leveling machines offers a wide range of benefits, making them a valuable investment for any construction project:

- Increased Precision and Flatness

Traditional manual leveling methods are prone to human error and uneven finishes. Concrete floor leveling equipment uses advanced control systems to achieve exact surface tolerances, resulting in flatter and more consistent floors. - Enhanced Productivity

These machines significantly reduce the time and labor required for concrete leveling. What once took hours can now be completed in a fraction of the time, allowing for faster project completion and reduced labor costs. - Improved Quality and Durability

With proper compaction and smooth finishes, the resulting concrete surfaces are stronger, more resistant to wear, and longer-lasting. This is particularly important for industrial and commercial floors subjected to heavy traffic. - Labor Savings

By automating much of the leveling process, fewer workers are needed on-site, and those who are present can focus on higher-value tasks. This is especially beneficial in regions with labor shortages or high labor costs.