Pile breaker is a kind of heavy mechanical equipment specially used for breaking concrete pile foundations and pile heads, which plays an important role in all kinds of construction and infrastructure projects. The hydraulic pile breaker can be divided into round pile breaking machine and square pile breaking machine according to the shape of the pile-cutting head. Concrete pile cutting machine is widely used in construction sites, road construction, bridge construction, dock construction, and other fields. It is a very important construction machinery equipment.

Pile Breaker Machines Parameters for Round Piles

| Model | YG-800 | YG-980 | YG-1150 | YG-1300 | YG-1500 | YG-1650 | YG-1800 | YG-2000 | YG-2150 | YG-2300 | YG-2500 |

| Applicable pile diameter | 600-800mm | 800-900mm | 1100-1150mm | 1150-1300mm | 1300-1500mm | 1500-1650mm | 1650-1800mm | 1800-2000mm | 2000-2150mm | 2150-2300mm | 2300-2500mm |

| Number of modules | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Machine weight | 2400kg | 2700kg | 3000kg | 3300kg | 3600kg | 3900kg | 4200kg | 4500kg | 4800kg | 5100kg | 5400kg |

| Applicable excavator model | 20-30T | 20-30T | 20-30T | 30-40T | 30-40T | 30-40T | Hydraulic pump station | Hydraulic pump station | Hydraulic pump station | Hydraulic pump station | Hydraulic pump station |

| Cylinder stroke | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm | 250mm |

| Working pressure | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa | 35Mpa |

| Oil storage capacity of a single module | 5L | 5L | 5L | 5L | 5L | 5L | 5L | 5L | 5L | 5L | 5L |

| Breaking force | 70T | 70T | 70T | 70T | 70T | 70T | 70T | 70T | 70T | 70T | 70T |

Advantages of the Modular Design

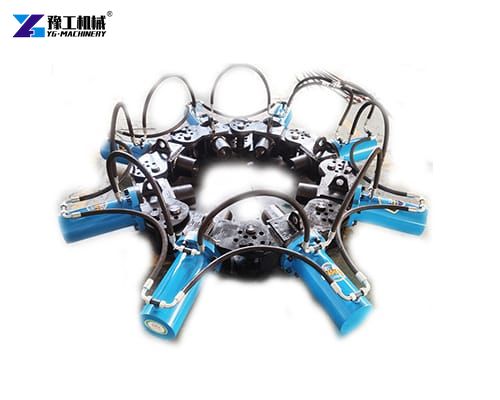

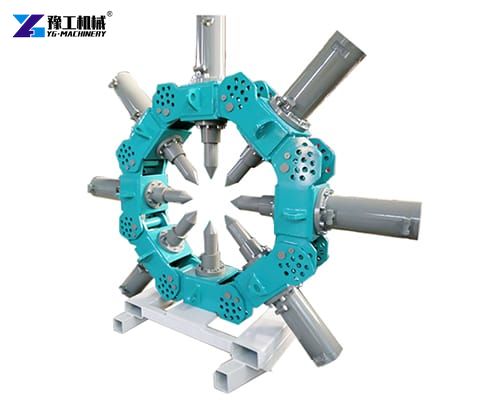

In the construction site, the concrete pile breaking machine can quickly and efficiently complete the demolition of the pile foundation, reduce the labor cost and construction time, and improve the construction efficiency. It adopts a highly modular combination design. Through the pin connecting module, it can be combined according to the need for different numbers of modules to cut off a certain range of diameters of the pile head. This design not only improves the versatility and economy of the equipment but also facilitates the installation and disassembly of the equipment.

Pile Breaker Machines Applications

- Bridge construction: used for cutting and clearing pile foundations.

- Tunnel construction: handling pile foundations or other obstacles.

- Airport construction: removing pile foundations in runways, aprons, and other areas.

- Water conservancy project construction: clearing pile foundations in rivers, lakes, and other waters.

The Mechanics of Efficiency – How Does A Pile Breaker Work?

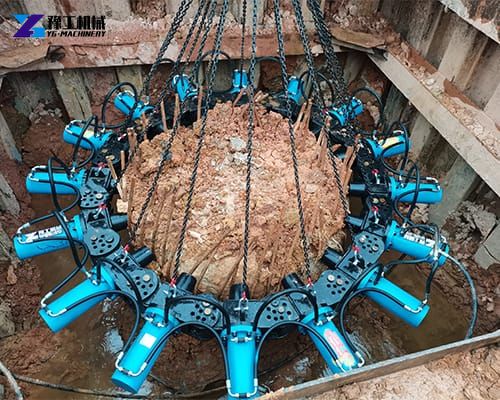

A pile breaker functions on a relatively simple yet highly effective principle of horizontal pressure. The machine consists of several interconnected hydraulic cylinders, each equipped with a specially hardened chisel or point. These modules are linked together to form a ring that encircles the concrete pile. When the hydraulic system is activated, the cylinders extend simultaneously, driving the chisels into the concrete. Because the pressure is applied from all sides toward the center, the concrete is crushed and fractured cleanly. One of the greatest advantages of this method is the preservation of the reinforcement bars (rebar).

Safety Advantages of Using A Pile Breaker

Construction safety is a top priority worldwide, and the pile breaker has transformed safety practices in pile trimming operations. Manual methods expose workers to flying debris, excessive noise, and repetitive strain injuries. By contrast, a pile breaker allows operators to work from a safe distance using hydraulic controls. Debris is contained, noise levels are reduced, and the risk of accidents decreases significantly.