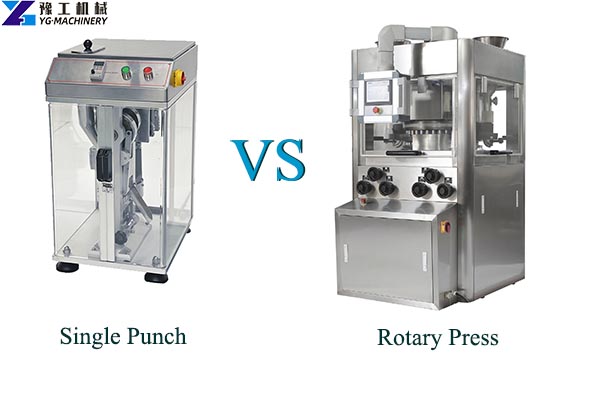

Do you know how the candies and pills we eat are made? It is made by direct compression using raw materials of powder or granules. The equipment for pressing raw materials is a tablet press. With the rapid development of the market economy, many items that need to be suppressed appear on the market. Such as effervescent tablets, camphor balls, health food, veterinary medicine tablets, chemical tablets, tea cubes, and compressed biscuits. The emergence of these products has led to the rapid development of tablet presses. The currently commonly used tablet presses are single punch tablet machines and rotary tablet press machines. Do you know the difference between single & multi-station rotary presses?

Single Punch Tablet Machine

The single punch tablet press is the earliest piece of equipment developed, and it has only one pair of dies. When working, the punch moves up and down to press the granular raw materials into flakes. The output of the single-punch tablet press is generally 80 tablets per minute, and it is generally used for experiments or small-scale production. The flower basket tablet press developed later is similar to the single-punch tablet press.

Multi Station Rotary Press

With the development of the economy, single-punch tablet presses can no longer meet the production needs of the market. Therefore, the rotary tablet press came into being. Moreover, the rotary tablet press is currently the most widely used equipment. The multi station rotary press adopts multiple punches that make circular motions according to a certain trajectory. There are many types of rotary tablet presses, according to the number of punches, there are 16 punches, 19 punches, 27 punches, 33 punches, 55 punches, etc.

Difference between Single & Multi Station Rotary Press

Different in Nature

The single-punch tablet press is a small electric continuous tablet press, and it can also be hand-cranked. The rotary tablet press is a multi-station rotary tablet press. The speed of the turntable, the filling depth of the material, and the thickness of the tablet can be adjusted during tablet pressing.

Application is Different

The production output of the single-punch tablet press is not high, so it is mostly used in laboratories for experiments or small-volume production. The rotary tablet press has multi-station simultaneous production, and the production output is high. Therefore, rotary tablet presses are widely used in food factories, pharmaceutical factories, factories, etc.

Die Installation is Different

Since the single-punch tablet press and the multi station rotary press have different numbers of dies, and the machine structures of the two are not the same, the dies are installed differently. If you are interested in our single punch or rotary tablet presses, please leave us a message.