Egg tray moulding machine is a specialized industrial system designed to manufacture egg trays and similar protective packaging products from waste paper pulp. By using recycled paper materials such as old newspapers, cartons, and office paper, the machine converts waste into durable, lightweight, and biodegradable packaging products. The egg tray making machine is widely used in poultry farming, egg processing plants, food logistics, agricultural packaging, and export-oriented businesses. This process aligns with global efforts to reduce plastic usage and promote circular economy practices.

Egg Tray Making Machine Parameters

| Model | YG-1000-3X1 | YG-1500-4X1 | YG-2500-3X4 | YG-3000-4X4 | YG-4000-4X8 | YG-5000-5X8 | YG-7000-6X8 |

| Capacity/hour | 1000pcs/h | 1500pcs/h | 2500pc/h | 3000pcs/h | 4000pcs/h | 5000pcs/h | 7000pcs/h |

| Power/hour | 38kw | 38kw | 55kw | 60kw | 95kw | 95kw | 120kw |

| Voltage | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz |

| Weight | 2500kg | 3000kg | 4000kg | 4800kg | 7000kg | 8000kg | 10000kg |

| Dimensions (main machine) | 2600*2200*1900mm | 2800*2200*1900mm | 2900*1800*1800mm | 3250*1800*1800mm | 3250*2300*2500mm | 3700*2300*2500mm | 3200*2300*2500mm |

| Paper consumption/hour | 80kg | 120kg | 200kg | 240kg | 320kg | 400kg | 480kg |

| Water consumption/hour | 160kg | 240kg | 400kg | 480kg | 640kg | 800kg | 960kg |

| Drying | Dry naturally | Dry naturally | Multi-layer drying | Multi-layer drying | Multi-layer drying | Multi-layer drying | Multi-layer drying |

Main Components of Egg Tray Moulding Machine

An egg tray moulding machine consists of several key components, each playing a crucial role in the overall production process. Understanding these components helps users better operate, maintain, and optimize the machine.

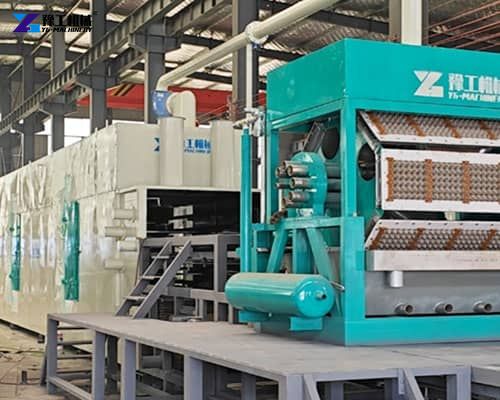

- The pulping system is the foundation of the entire machine. It includes a hydraulic pulper, water tanks, and pulp pumps. Waste paper is broken down into fiber slurry with controlled consistency, ensuring uniform thickness and strength in the final egg trays.

- The molding system is the core of the egg tray moulding machine. It includes molding molds, transfer molds, vacuum pumps, and air compressors. The molds are usually made of aluminum or plastic, designed according to specific egg tray dimensions. Vacuum suction draws pulp onto the mold surface, forming the egg tray shape.

- The drying system removes moisture from the wet molded trays. Depending on the production scale and investment budget, drying can be done using natural air drying, brick kiln drying, metal drying lines, or multi-layer drying ovens. Efficient drying directly affects production speed and product quality.

- The stacking and packaging system automatically collects dried egg trays and stacks them in neat piles. This reduces labor costs and improves production efficiency. Some advanced egg tray production machine models.

Working Principle of Egg Tray Manufacturing Machine

The working principle of an egg tray moulding machine is based on pulp molding technology. The process begins with pulping, where waste paper is mixed with water and mechanically processed into uniform pulp. This pulp is then transferred to the molding section, where vacuum suction forms the pulp into the shape of egg trays using customized molds. After molding, the wet egg trays are dried and stacked for packaging or direct use.

Why Invest In Paper Egg Tray Making Machine?

From a business perspective, the egg tray manufacturing industry offers several unique advantages that mitigate risk and ensure long-term viability.

- Low Raw Material Costs

Unlike many manufacturing sectors that depend on expensive raw polymers or metals, the egg tray industry thrives on waste. In many regions, waste paper can be sourced for a fraction of the cost of virgin materials. - High Market Demand

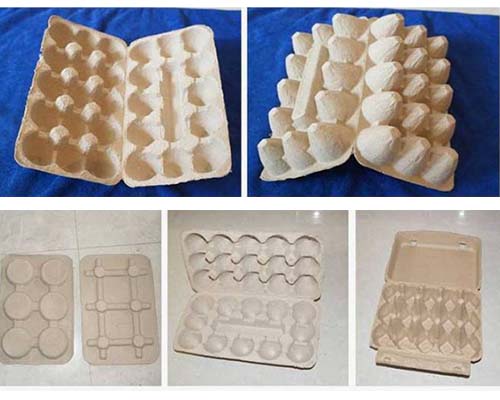

The consumption of eggs is a global staple. As the population grows, so does the need for protective packaging. Furthermore, supermarkets and retailers are under pressure to eliminate plastic foam (EPS) packaging, leaving molded pulp as the primary alternative. - Versatility and Scalability

An egg tray moulding machine is not a one-trick pony. By investing in different mold sets, a business can pivot to produce shoe trees, electric component trays, or seedling pots, allowing the company to diversify its revenue streams based on seasonal demand.