Kraft paper slitting machine is a specialized industrial machine designed to cut wide kraft paper rolls into narrower rolls with consistent width, clean edges, and high accuracy. Kraft paper, known for its strength, durability, and eco friendly properties, is widely used in packaging, printing, laminating, and many other fields. To make kraft paper suitable for different applications, it must be slit into specific sizes required by downstream processes. The slitting machine fulfills this need by unwinding the parent roll, performing precise cutting with slitting tools, and rewinding the slit materials into tidy finished rolls.

Characteristics of Kraft Paper Slitter Rewinder

Kraft paper slitting machines offer a combination of mechanical strength, intelligent controls, and adaptable configurations. Their most notable features include high cutting precision, adjustable speed, strong tension management, and the ability to handle kraft paper of various thicknesses. It also integrate user friendly control interfaces, digital measurement displays, and quick adjustment mechanisms for changing roll thickness or cutting width. Stability during high-speed operation is another important characteristic. Since kraft paper can vary in density and stiffness, the machine must maintain smooth running even at high line speeds. Some machines may also incorporate safety mechanisms such as protective covers, emergency stops, overheat protection, fault alarms, and anti-jam configurations. These not only enhance safety but also improve operating efficiency by reducing downtime.

Structural Components of Kraft Paper Slitting Machine

- Unwinding Unit

This section holds the parent jumbo roll and ensures smooth unwinding. It includes hydraulic or pneumatic lifting devices, tension controllers, brake systems and roll centering mechanisms. - Slitting Section

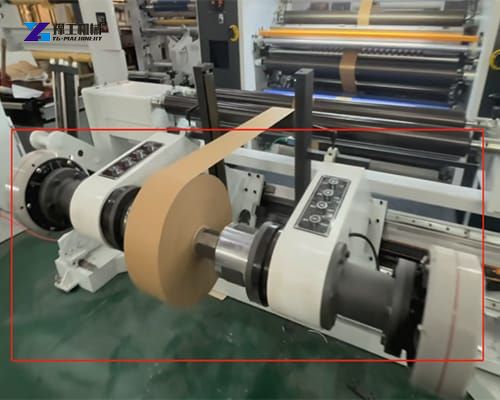

At the heart of the machine, the slitting section is equipped with upper and lower circular blades or razor blades. The blade holders, shafts and positioning systems allow rapid adjustment for different slitting widths. - Rewinding Unit

After slitting, the web path moves to the rewinding unit where the narrower strips are rewound into individual finished rolls. Differential shafts or surface rewinding systems help maintain equal tightness across all rolls. - Tension Control System

This system manages the tension in the unwinding, slitting and rewinding phases using sensors, dancing rollers and servo motors. Proper tension ensures smooth operation, accurate cutting and strong roll formation. - Edge Position Control

Also known as automatic edge correction, this system ensures that the paper edges remain aligned to avoid slant trimming or uneven slitting.

Applications of Kraft Paper Slitter

Kraft paper slitting machines serve numerous industries due to the wide use of kraft paper as a packaging and industrial material. Common applications include corrugated box manufacturing, wrapping paper production, laminating material preparation, self-adhesive kraft paper tape production, food packaging paper conversion, and industrial cushioning materials. In the logistics and e-commerce sectors, where kraft paper is widely used for protective wrapping and eco-friendly packaging, slitting machines help companies maintain an efficient supply of custom-sized rolls. In addition, small paper converting workshops and large paper mills alike benefit from these machines in handling bulk paper material.

Buying Considerations

Choosing the right kraft paper slitting machine requires careful evaluation of several factors:

- Production capacity

Estimate your daily, weekly, or monthly output to determine the machine size and speed that matches your needs. - Material thickness range

Ensure the machine is compatible with the thickness and type of kraft paper you commonly use. - Control system sophistication

User-friendly digital interfaces and automation features reduce training time and improve efficiency. - Tension control technology

For high-quality rolls, advanced automatic tension control is strongly recommended. - Machine durability

A sturdy frame and high-grade components extend service life and improve long-term stability.