Tyre recycling machine for sale refers to a series of recycling machines for processing waste tires, including cutting, crushing, magnetic separation, fiber separation, fine crushing, grinding, etc. The process includes crushing, magnetically separating, separating fiber and producing rubber powder for waste tires, separating steel wire fiber and rubber components in the tires. There are different tire processing machines. People can choose the corresponding machines to match a recycling line according to actual needs. If you want more details about the tyre recycling machine for sale or do not know how to select it, please get in touch with us today and tell us your requirements.

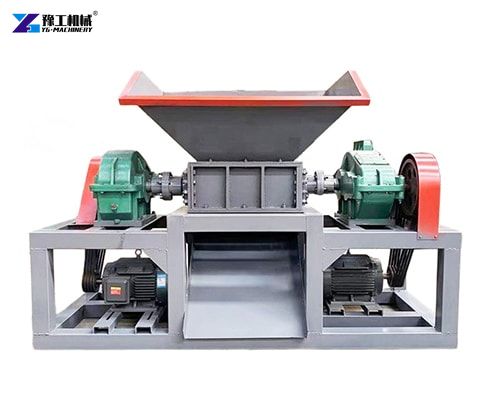

Waste Tyre Shredder Parameter

| Model | YG-1000 |

| Power | 37KW level, 6*2 Units |

| Speed | 8-15 r/min |

| Frame | Welded from 120*120mm square steel |

| Cutter head hardness range | 53-55 hardness |

| Cutterhead diameter | 400mm |

| Cutterhead thickness | 50mm |

| Shaft length | 190mm |

| Dimension | 3800(L)*2000(W)*2300(H)mm |

Notice: The tire shredder machine body adopts a split type for easy disassembly and assembly, welded with stainless steel plates. Overall dimensions of the machine can be designed according to container size or customer needs.

Functions of Tyre Recycling Machines for Sale

- Waste tire wire drawing machine: extracts the steel wire from the tire

- Ring cutting machine: used to cut the tire sidewalls and inner mouths

- Automatic strip cutting machine: cuts the tyre into long strips

- Block cutting machine: used to cut strip tires into 3-8 cm blocks

- Tyre shredder: shreds the tire into blocks, and the size of the output can be controlled by adding a screen, as the core of the tyre recycling machine for sale

- Magnetic separator: use the magnetic field to separate the steel wire after tire crushing.

- Fiber separator: take advantage of mechanical or chemical methods to separate the fibers after tire crushing for further processing and utilization.

- Rubber crusher: the main equipment of the crushing production line, used to crush rubber blocks after tire pretreatment. Mainly crushes rubber blocks into powder and particles

- Rubber powder production equipment: processes the rubber powder after tire crushing to make recycled rubber or other high value-added products.

- Auxiliary equipment: conveyor, screening machine, air separator, magnetic separator, rubber powder cooling equipment, electric control cabinet.

Working Process of the Waste Tire Recycling Line

Firstly, pull out the steel wire from the tire by tire wire drawing machine. Secondly, cut the tyre to two or three part by the ring cutter. Thirdly cut the waste tire into the strips. Then cut the strip to pieces through the tire lump cutter. Separate the steel wire by a magnetic separator. Finally, process it into rubber powder, and process into recycled rubber or other high value-added products. Or it can use the tire shredder directly after drawing the steel wire out instead of ring cutter, strip cutter, and lump cutter as one of the tyre recycling machine for sale.

Uses of Tire Particles

- Tire particles can be used as fuel. Waste tire particles have high calorific value and are one kind of the ideal fuels for thermal power plants, cement plants, and steel mills.

- 3-28mm particles can be used as fillers for rubber plastic tracks, sports fields, and football fields.

- Tire particles can be used as playground fillers, rubber rolls, rubber flower pots, etc.

- The tire particles can be used for oil refining

How to Extend the Service Life of Tyre Recycling Machine for Sale?

- Start the equipment, and run it empty for 1-3 minutes before placing materials, which can extend the service life of the blade.

- After the equipment finishes the shredding process, do not shut down the equipment until the material is completely discharged.

- Take out steel wire from the waste tires before shredding the tire in the tire shredder. It can reduce blade wear and tear for long service life.