Portable sandblasting machine is a self-contained system designed to propel abrasive materials under high pressure onto a surface to propel abrasive media at high velocity against a surface to clean, etch, or prepare it. These machines prioritize mobility, featuring lightweight frames, ergonomic handles, and compact tanks. They operate using compressed air to blast media like sand, glass beads, or steel grit, effectively stripping rust, paint, or contaminants from substrates.It has become essential in industries such as construction, shipbuilding, automotive repair, and metal fabrication. Whether it is removing rust, cleaning old paint, or preparing surfaces for coating, the sandblasting machine offers a fast and efficient solution. Its mobility and efficiency make it the preferred choice for businesses that require on-site cleaning and surface treatment.

Dry Sand Blasting Machine Parameters

| Diamter(mm) | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Height(mm) | 1100 | 1150 | 1200 | 1350 | 1900 | 2000 | 2000 |

| Volume( m³ ) | 0.15 | 0.2 | 0.3 | 0.4 | 0.6 | 0.8 | 1 |

| Pressure | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa |

| Efficiency(m²/h) | / | / | 5- 10 | 6-11 | 10-12 | 10-20 | 10-30 |

| Air consumption | 4-6m³/min | 4-6m³/min | 4-6m³/min | 4-6m³/min | 4-6m³/min | 4-6m³/min | 4-6m³/min |

Wet Sandblasting Machine Specifications

| Diamter(mm) | 500 | 600 | 800 |

| Height(mm) | 1750 | 1750 | 1950 |

| Volume(L) | 200 | 300 | 550 |

| Pressure(MPa) | 0.8 | 0.8 | 0.8 |

| Efficiency(m²/h) | 15 | 15 | 15 |

| Air consumption | 6³/min | 6³/min | 6³/min |

Features of A Portable Sandblasting Machine

- Mobility and Compact Design

The portable design allows operators to move the machine easily from one job site to another. Most models come with wheels, handles, and lightweight construction to ensure effortless transportation. - Abrasive Material Compatibility

These machines can handle various abrasive media such as silica sand, glass beads, aluminum oxide, steel grit, and so on. - Durable Build Quality

The machine is typically made of corrosion-resistant steel or heavy-duty alloys to withstand constant exposure to abrasive particles.

Working Principle: How Does the Sandblasting Machine Work?

The portable sandblasting machine itself is a pressurized tank, or pot, filled with the chosen abrasive media. Compressed air, supplied by a separate air compressor of sufficient capacity, enters the pot, pressurizing it. This air follows two paths. A primary line pressurizes the pot itself, creating a downward force on the abrasive. A second line, known as the blast line, is connected to a valve at the bottom of the pot.

When the operator pulls the trigger on the blast nozzle, it activates a remote control valve on the pot. This opens the pathway, allowing the compressed air to rush into the blast line. As this high-speed air passes through a venturi section at the bottom of the pot, it creates a suction effect, drawing the abrasive media into the air stream. The mixture of high-pressure air and abrasive then travels through a reinforced hose and exits the nozzle at tremendous speed. The result is a concentrated, controllable stream that impacts the surface, effectively stripping away unwanted material through mechanical action.

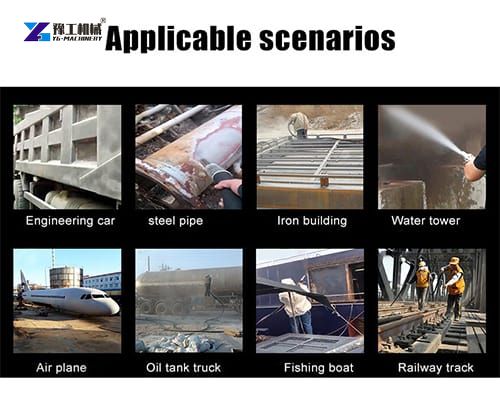

Applications of Portable Sandblasting Machines

- Metal Surface Cleaning

Widely used in removing rust, mill scale, and welding slag from steel structures. - Automotive Industry

Essential for restoring car bodies, cleaning engine parts, and preparing surfaces for repainting. - Shipbuilding And Marine Industry

Ideal for removing barnacles, algae, and corrosion from ship hulls.

How to Choose The Right Sandblasting Machine?

When selecting a portable sandblasting machine, consider the following factors:

- Purpose And Application

Choose based on whether you need it for heavy-duty industrial use or smaller restoration projects. - Abrasive Media Compatibility

Ensure the machine supports the abrasive material suitable for your application. - Tank Size And Capacity

Larger tanks are better for continuous blasting, while smaller tanks are ideal for light, mobile tasks. - Air Compressor Requirements

Match the machine’s air consumption with your compressor’s capacity to ensure smooth operation. - Durability And Safety

Look for machines made from strong, corrosion-resistant materials with built-in safety systems. - Budget And Maintenance Costs

Consider not only the purchase price but also long-term maintenance and consumable costs.