The chain trenching machine is a piece of machinery designed for excavating earthworks like drainage ditches, channels, and trenches. It adopts a chain transmission system. In construction projects, chain trenchers enhance efficiency, lessen labor demands, ensure high-quality ditch excavation, and lower earthwork costs. They are commonly employed in various sectors, including road construction, agricultural pipeline installation, water conservation projects, orchards, vegetable gardens, and urban and rural fiber optic installations, for trenching, fertilizing, and managing drainage and irrigation. There are different specifications available. People can choose the suitable machine according to their real needs.

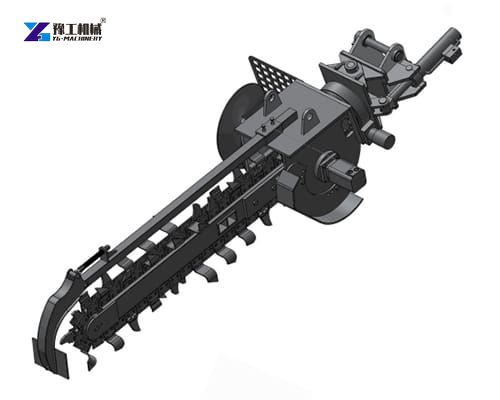

Chain Link Rock Ditching Machine

Chain trenching machine is a specialized tool for trenching in rocky terrain. It can efficiently navigate obstacles and shallow ditches. Its casing includes auxiliary supports to regulate excavation depth, and discharge ports are on both sides for removing excavated materials. The chain length can be customized to meet customer requirements, and the smooth groove contour provides results that surpass those of conventional crushing methods. This makes it an excellent option for rock trenching and a true representation of advanced technology.

Chain Rock Trenching Machine Parameters

| Model | YG-1 | YG-2 | YG-3 | YG-4 |

| Suitable excavator | 6-9T | 10-18T | 20-27T | 30-40T |

| Trench width | ≤100mm | ≤180mm | ≤240mm | ≤300mm |

| Trench depth | ≤1000mm | ≤1200mm | ≤1500mm | ≤2000mm |

| Maximum pressure | 35Mpa | 35Mpa | 35Mpa | 35Mpa |

| Overall length | ≤2000mm | ≤2300mm | ≤2400mm | ≤3400mm |

| Overall weight | ≤1500mm | ≤2500mm | ≤4000mm | ≤6000mm |

Chain Soil Trencher for Sale

This chain soil ditching machine is a trencher designed for excavators. It can effectively cross obstacles and low-lying ditches for trenching operations. It is widely used in underground construction of pipelines, wires and cables, and optical fibers. The machine uses a low-speed, high-torque motor to drive the alloy chain to rotate, and the alloy cutter on the chain cuts the soil. At the same time, the spiral is used to neatly pile the excavated soil on one side of the trench. It solves the trenching problem in difficult terrain, improves construction efficiency, and brings higher returns.

Chain Soil Trenching Machine Parameters

| Model | YG1200 | YG1500 |

| Suitable excavator | 6-9T | 10-18T |

| Trench width | ≤200mm | ≤300mm |

| Trench depth | ≤1200mm | ≤1500mm |

| Maximum pressure | 24Mpa | 24Mpa |

| Recommended flow rate | 80L | 120L |

| Overall length | ≤2270mm | ≤2570mm |

Benefits of a Chain Trenching Machine

- High efficiency and energy conservation: The chain drive effectively transmits power to the working components, enhancing efficiency and reducing energy consumption.

- Consistent vibration: The use of linear vibration results in a more uniform trenching effect and improved trench quality.

- Easy adjustment: The depth and width can be easily modified to meet specific operational requirements, making it user-friendly.

- Strong adaptability: It is suitable for various soil types and working conditions, accommodating diverse operational needs.

- Safe operation: With a robust and stable structure, the operation is straightforward, ensuring high safety standards and minimizing risks for operators.

- Excellent excavation quality: The trenches produced have consistent depth, uniform width, and adjustable dimensions, significantly enhancing excavation quality and efficiency.