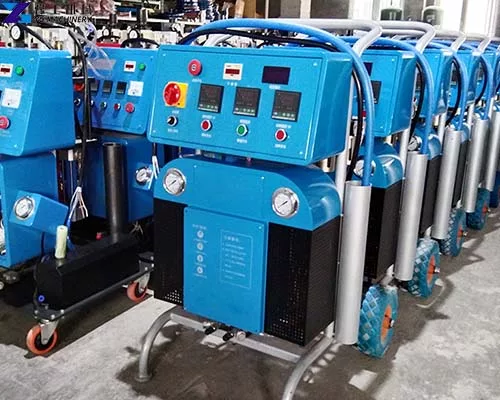

The polyurethane foam spray machine can be used for spraying and pouring polyurethane rigid foam, which plays the role of heat insulation and waterproofing. It is widely used in building exterior wall thermal insulation spraying, refrigerated thermal insulation spraying, roof thermal insulation spraying, etc. The polyurethane foam spray machine can also be used to spray two-component materials such as PU Foam and Polyurea. The products produced by high-pressure polyurea spray machines have the characteristics of uniform and smooth surfaces, no graininess, and reliable quality. The polyurethane spraying machine has been widely used in the construction industry, aviation, automobile, and other industries, playing a very good role in thermal insulation and sound insulation.

Polyurethane Spraying Machine Parameters

| Model | Host heating power(KW) | Pipe heating power(KW) | Heating power(KW) | Motor Power | Total power(KW) | Drive mode | output flowKg/Min | Support pipeline(m) | Power(V) |

| YG-III(H) | 7 | 2.5 | 9.5 | / | 9.5 | Pneumatic | 2-10 | 75 | 380 |

| YG-Q2600 | 9 | 2.5 | 11.5 | / | 11.5 | Pneumatic | 2-10 | 90 | 380 |

| YG-III(D) | 8 | 1 | 9 | / | 9 | Pneumatic | 2-10 | 30 | 380 |

| YG-Q2600(D) | 10 | 1 | 11 | / | 11 | Pneumatic | 2-10 | 30 | 380 |

| YG-H5600(D) | 18.5 | 1 | 19.5 | 3.75 | 23.5 | Hydraulic | 2-12 | 30 | 380 |

| YG-H-T40(D) | 18.5 | 1 | 19.5 | 3.75 | 23.5 | Hydraulic | 2-12 | 30 | 380 |

| YG-Q30 | 12.5 | 2.5 | 15 | / | 15.5 | Pneumatic | 2-10 | 90 | 380 |

| YG-Q40 | 14.5 | 3.5 | 18 | / | 18 | Pneumatic | 2-10 | 90 | 380 |

| JX-H5600 | 18.5 | 3.5 | 22 | 3.75 | 26 | Hydraulic | 2-12 | 105 | 380 |

| YG-H-T40 | 18.5 | 3.5 | 22 | 3.75 | 26 | Hydraulic | 2-12 | 105 | 380 |

| YG-H5600(T) | 21 | 4 | 25 | 3.75 | 29 | Hydraulic | 2-8 | 120 | 380 |

| YG-H-T50 | 21 | 4 | 25 | 3.75 | 29 | Hydraulic | 2-8 | 120 | 380 |

The above is the detailed parameter list of polyurethane, PU foam, and polyurea spraying machines. Contact us to get the polyurethane spraying machine price. In addition, YG also provides construction spraying machines such as mortar spraying machines, shotcrete machines, and GRC spray machines.

Advantages Of Polyurethane Machine In the Construction Industry

- Available in many shapes. It can be directly sprayed and foamed to any shape, such as round, spherical, or other irregularly shaped complex objects, etc.

- The spraying shape is consistent with the shape of the substrate object, there is no joint, and the heat preservation effect is good.

- It is especially suitable for heat insulation of large-area and special-shaped objects, with fast forming speed and high production efficiency.

- In addition, the objects sprayed with a polyurea spray machine also have the characteristics of strong hydrophobicity, strong sealing, and stable performance.

Wide Application Of Polyurea Spray Machine

Polyurethane is mainly used for thermal insulation, heat insulation, sound insulation, etc. Therefore, polyurea spray machine is widely used in various heat preservation, heat insulation, and sound insulation projects. For example, interior and exterior wall insulation spraying, cold storage insulation spraying, roof waterproof insulation spraying, KTV sound insulation project, pipeline insulation, and other projects.

Working Principle of PU Foam Spray Machine

Polyurethane rigid foam is two kinds of liquids before molding. It is prepared into solid raw material by a PU foam spray machine. A polyurea spray machine is also called a high-pressure polyurethane spray machine. When using high-pressure spraying, polyurethane will undergo high-speed impact and vigorous rotation in the mixing chamber under the space, and then fully mix. Then it forms a fine droplet shape through the nozzle of the spray gun and sprays evenly on the surface of the object to be sprayed.

High-Quality Properties Of Polyurethane Rigid Foam

Polyurethane material is the abbreviation of polyurethane, which is an organic polymer material. Rigid polyurethane foam has the characteristics of good thermal insulation effect, waterproof, flame retardant, strong adhesive ability, and high compressive strength. The rigid foam polyurethane spraying process has the characteristics of generous columns, no shedding, strong fire resistance, good water resistance, strong air permeability, and fast construction speed. Therefore, rigid polyurethane foam is widely used in various thermal insulation, heat insulation, sound insulation, and other projects.

Features Of Polyurethane Foam Spray Machine

- Using a powerful composite heater, it heats up quickly and maintains a fixed temperature even when spraying at the maximum flow rate.

- Hydraulic two-component, simple operation, easy maintenance, economical and durable.

- The air of the spray gun is self-cleaning, and the equipment does not need to be cleaned.

- Equipment can be upgraded, LED anti-slip and wear-resistant large frequency, regular quantitative spraying, pipe lengthening, etc.

- Easy to form, high output, standardized finished product specifications and sizes, and assembled construction.

- The product of the polyurethane spraying machine has no seams, the overall performance is good, and the heat preservation and waterproof performance are better than that of the polyurethane board.

- Used in various construction environments, suitable for spraying a variety of two-component materials, such as polyurea elastomers, polyurethane elastomers, polyurethane foam materials, polyurea, polyurethane adhesives, etc.